Elevating Partnerships, Ensuring Quality

Are you ready to establish strong and reliable partnerships with your suppliers? Let’s unravel the intricacies of this pivotal process and uncover how automation can optimize your supplier relationships and drive efficiency.

Understanding the process

Supplier homologation is the critical process of evaluating and approving potential suppliers before engaging in business transactions. It ensures that suppliers meet stringent criteria in terms of reliability, performance, and compliance with regulatory standards and industry requirements.

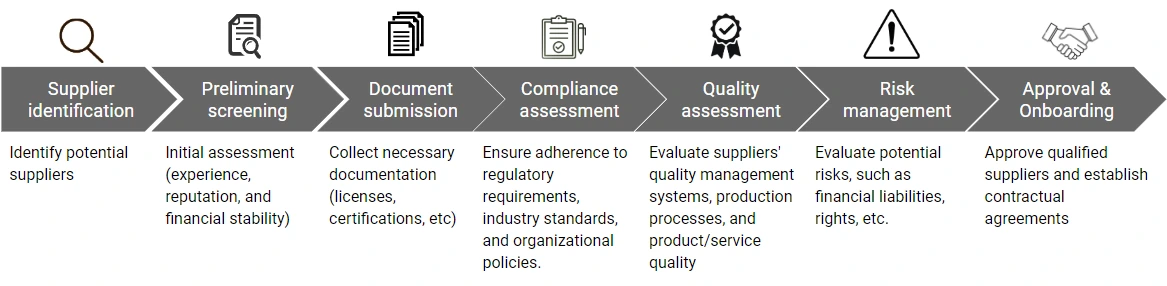

Steps in the process